MIM company Custom Metal injection molding parts Bluetooth TWS earphones hinges Powder Metallurgy Sintering

Material: STAINLESS STEEL, Stainless steel 316L

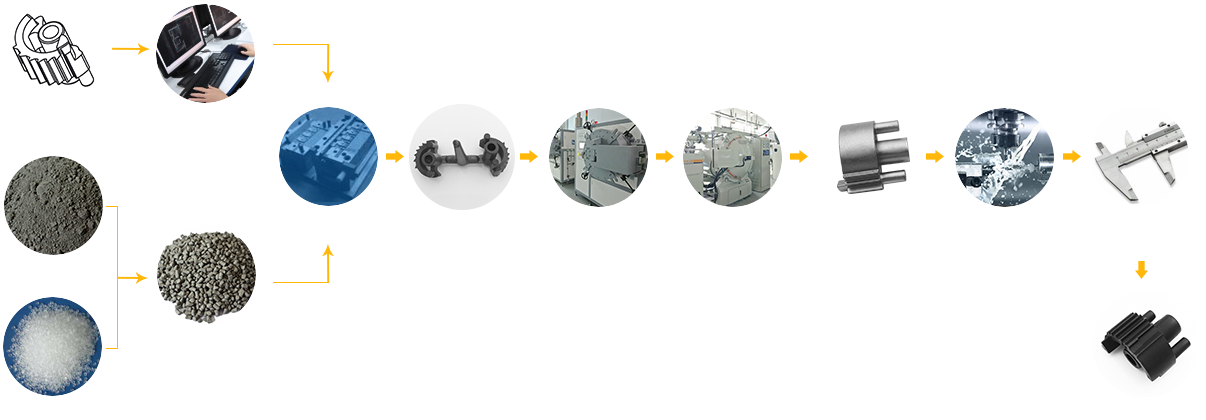

Sintering environment:Vacuum

Type: Solid

Sintering method: Solid phase sintering

Post-Sintering: Polishing,Wiredrawing,Sandblasting,Plating,Coated,etc.

Forming Method: Powder Injection Molding

Application:Manufacturing Plant.

.png-50)

.png-50)

.png-50)

.png-50)