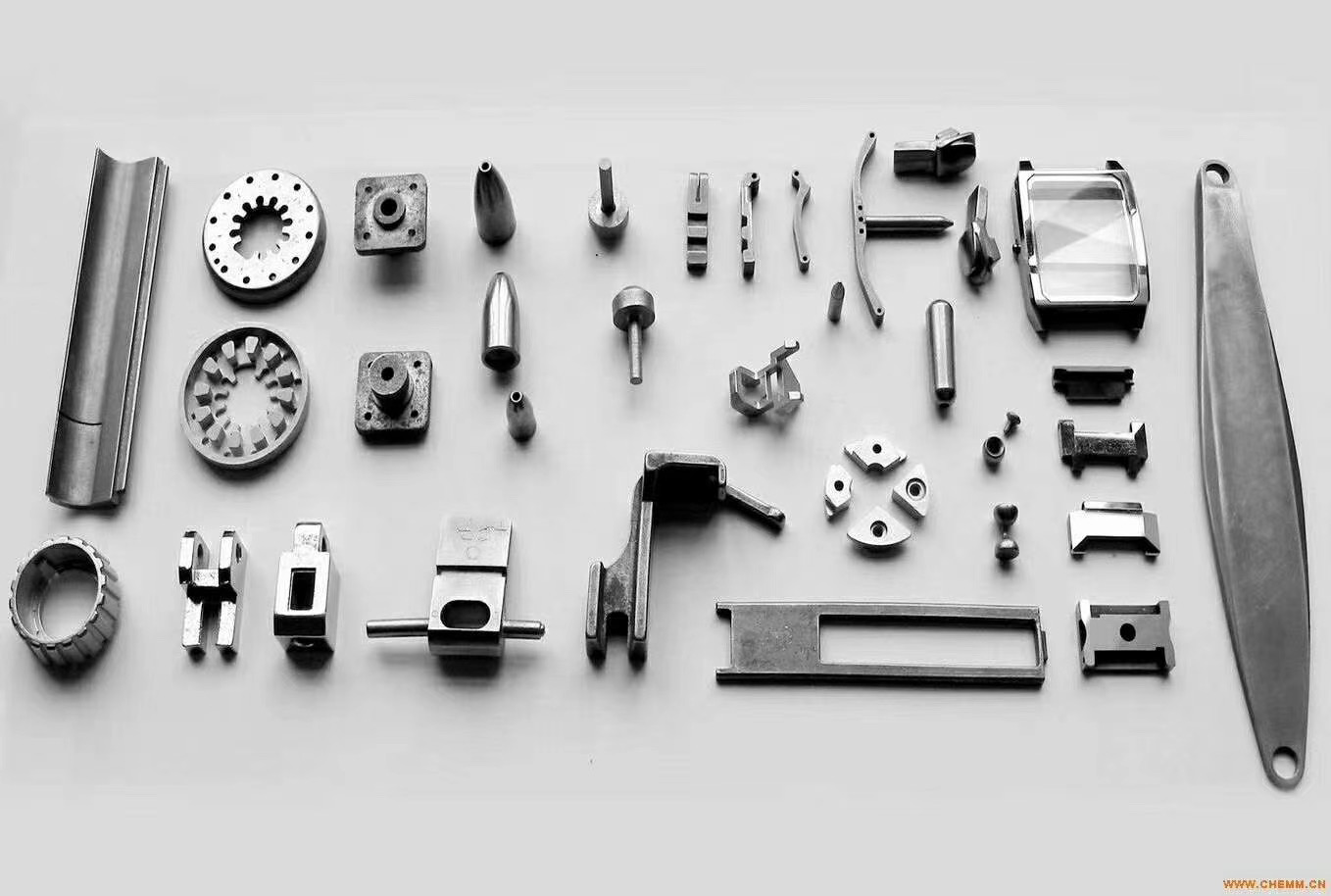

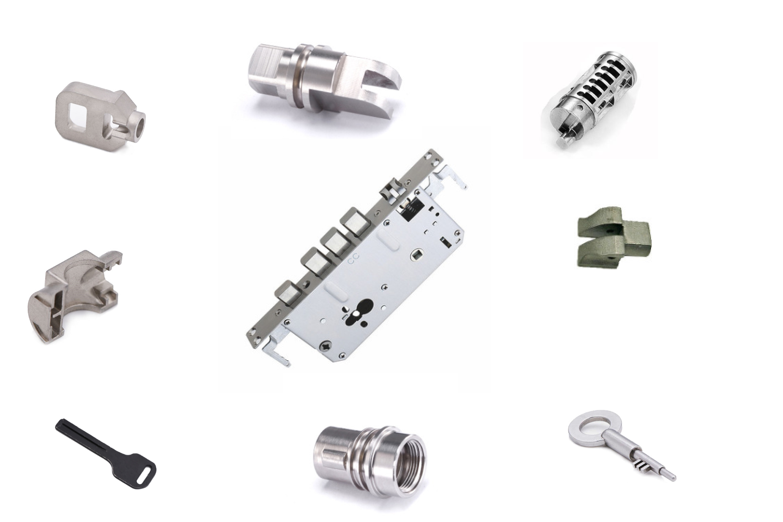

Why do your parts choose to use MIM production?

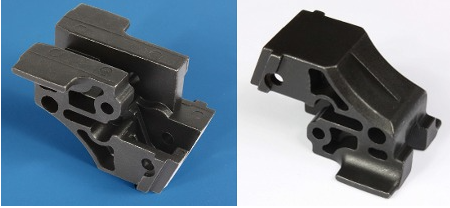

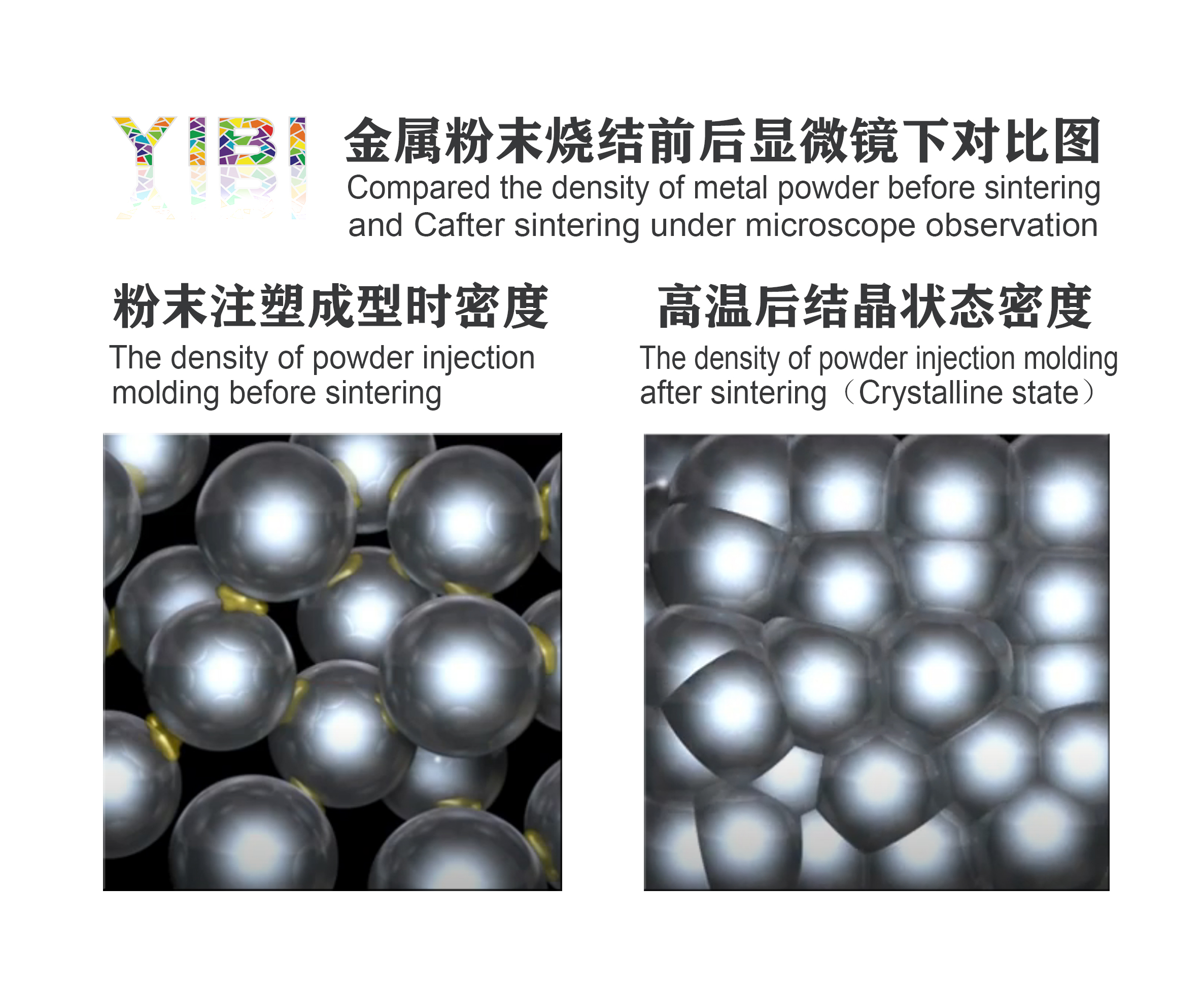

MIM technology is ideal for producing components of high mold complexity, such as undercuts and threads, without any subsequent machining required. Furthermore, it is possible to use materials not easily mechanically processed, for instance...